Taiwan YE FONG ALUMINIUM MILL

(Aluminium WIRE ROD/seamless TUBE/ BAR/ PROFILE/ PLATE)

(Focus on high strength Aluminium alloy such as 2024. 7050. 7075)

(Aluminium WIRE ROD/seamless TUBE/ BAR/ PROFILE/ PLATE)

(Focus on high strength Aluminium alloy such as 2024. 7050. 7075)

Ye Fong Aluminum Industrial Ltd. is the aluminum alloy manufacturer/mill in TAIWAN. Ye Fong has established indirect/direct extrusion pressers, and integrated with straightening, cold drawing lines and heat treating processes by ourselves .We provides worldwide customers with full customized product development, technical consulting and technical service. We produce aluminum alloy materials including Precision Extrusion & Cold drawn seamless TUBE, BAR, PROFILE, PLATE and HOT ROLLED WIRE ROD to global markets including high-end Aerospace, Marine Shipbuilding, Automotive, High Precision Machining, Medical, and Commercial ..etc.

Ye Fong is aluminum mill which award NADCAP (Heat Treating & NonDestructive Testing), AS9100, ABS, ISO 9001 and ISO 14001 and specialized in the aluminum materials of 7075, 7475, 7055, 7050, 4032, 2024, 2014, 2124,6061, 6082, 5083, 5052…more. Comply with international standards such as AMS (WW-T-700/QQ-A-200/QQ-A-225/QQ-A-250)/ASTM/DIN/JIS/BS L168 /EN…etc.

With our special HOT ROLLING technology (Not traditional Continuous Casting) we can process a wide range of sizes and alloys for aluminum wire rod(7075. 7050. 2024. 2014. 2017. 2117. 4032. 6061. 6056. 6082. 5056…etc), delivering fine grained structures with excellent formability at a competitive price. Special alloys, tempers, and tolerances are available ; Wire Surface Shaving is also available in house. Homogenization Treated & Inspected by Ultrasonic & Segregation Layer Removed & On-line Eddy Current Inspection. Main end use markets are aerospace, automotive, and general engineering fastener industries (Rivet/ Rivet Nut /Bolt/ Studs/Thread Insert/Collars ).

In our manufacturing plant we make use of a wide variety of precision extrusion presses (direct/indirect) & cold drawn machines, vertical and horizontal solution heat treatment & roller hearth furnaces as well as polishing machines and stretchers in house. In combination with our QA laboratory this machinery allows us to maintain the highest quality through our extrusion product portfolio including Extruded & Cod Drawn seamless Round Tubing, Rectangular Tubing, Square Tubing , Profile Tubing in various applications such as Fighter Jet Ejector Seat Structural Tube (2014 – T6/7075-T73511), Baggage Bar Tube (2024 – T3 /7075 – T4), Airplane Structural Tube (7075 – T651), Camera Lenses Tube (5056 – H32/H34/H112 ; 5052 – H112/H32/H34), Vessel Tube (5083 – H112) , Aircraft Seat Beam Tube, Medical Wheel Chair Tube (6061 -T6/ 6082/T6), Aircraft Tie Rod (2024 – T351), Helicopter Structural Beam(7075 – T651)…etc.

In our manufacturing plant we make use of a wide variety of precision extrusion presses (direct/indirect) & cold drawn machines, vertical and horizontal solution heat treatment & roller hearth furnaces as well as polishing machines and stretchers in house. In combination with our QA laboratory this machinery allows us to maintain the highest quality through our extrusion product portfolio including Extruded & Cod Drawn seamless Round Tubing, Rectangular Tubing, Square Tubing , Profile Tubing in various applications such as Fighter Jet Ejector Seat Structural Tube (2014 – T6/7075-T73511), Baggage Bar Tube (2024 – T3 /7075 – T4), Airplane Structural Tube (7075 – T651), Camera Lenses Tube (5056 – H32/H34/H112 ; 5052 – H112/H32/H34), Vessel Tube (5083 – H112) , Aircraft Seat Beam Tube, Medical Wheel Chair Tube (6061 -T6/ 6082/T6), Aircraft Tie Rod (2024 – T351), Helicopter Structural Beam(7075 – T651)…etc.

In our manufacturing plant we make use of a wide variety of precision extrusion presses (direct/indirect) & cold drawn machines, vertical and horizontal solution heat treatment & roller hearth furnaces as well as polishing machines and stretchers in house. In combination with our QA laboratory this machinery allows us to maintain the highest quality through our extrusion product portfolio including Extruded & Cold Drawn Aluminum Round Bar, Aluminum Flat Bar, Aluminum Hexagon Bar in various applications such as Aircraft Component (2024 – T351/T851;7075 – T651/T7351; 7050 – T7451/T7651; 2014 -T4/T6), Forging Material (2014/7050/7075-TO), Fastener Rivet Nut/Screw (2024 -T3/T351/T851 ; 2011 -T3/T8 ; 7075 -T6 /T651), Vessel Component (5083-H321/H116), Electronic Component (7075 -T651), Tooling Component (6082/7075-T651), Gear Crank (7075 – T651/T7351)…etc.

YEFONG ALUMINIUM offers premium solutions featuring BS L168 Aluminum Alloy with NADCAP heat treating certification to guarantee the batch uniformity and quality consistency.

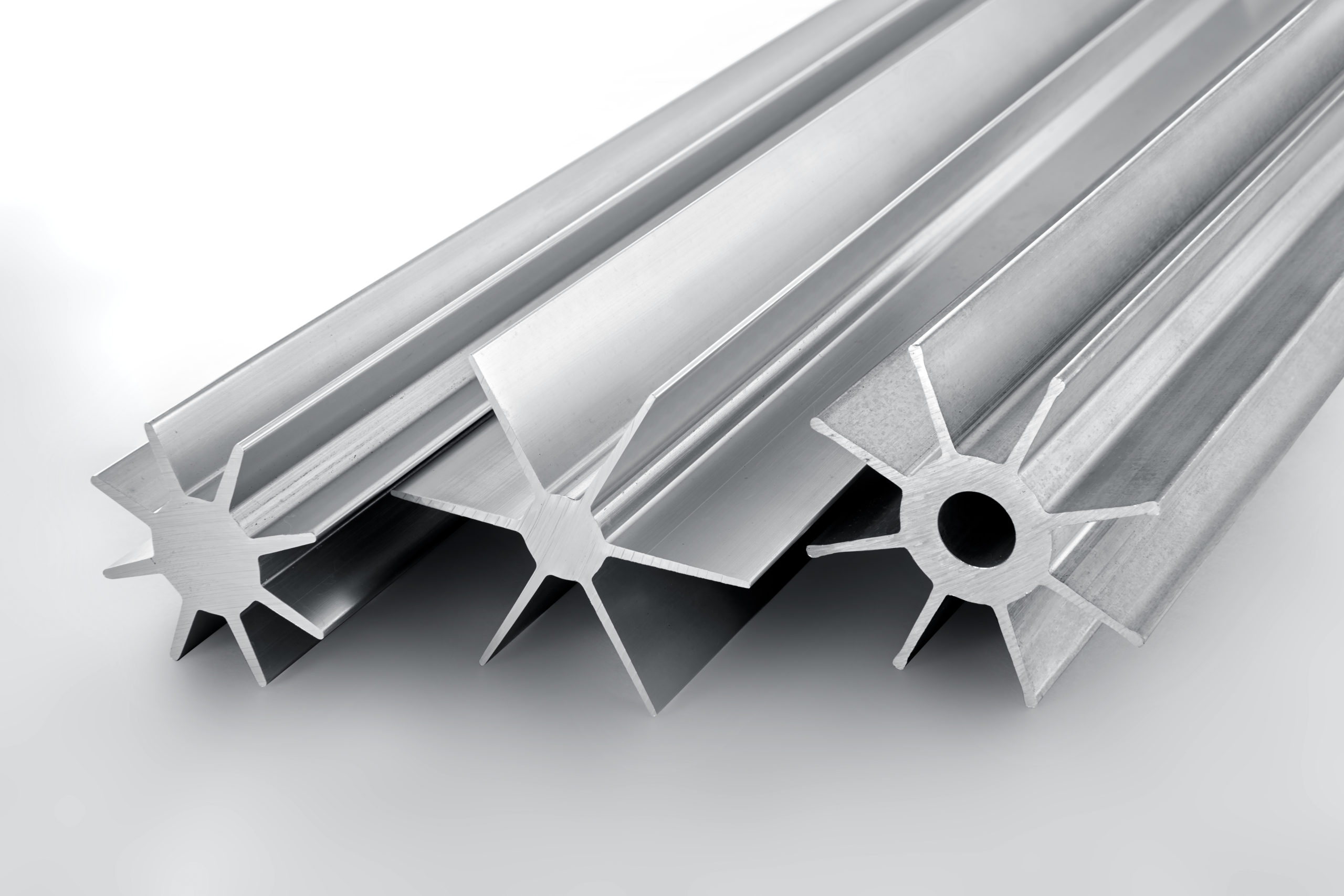

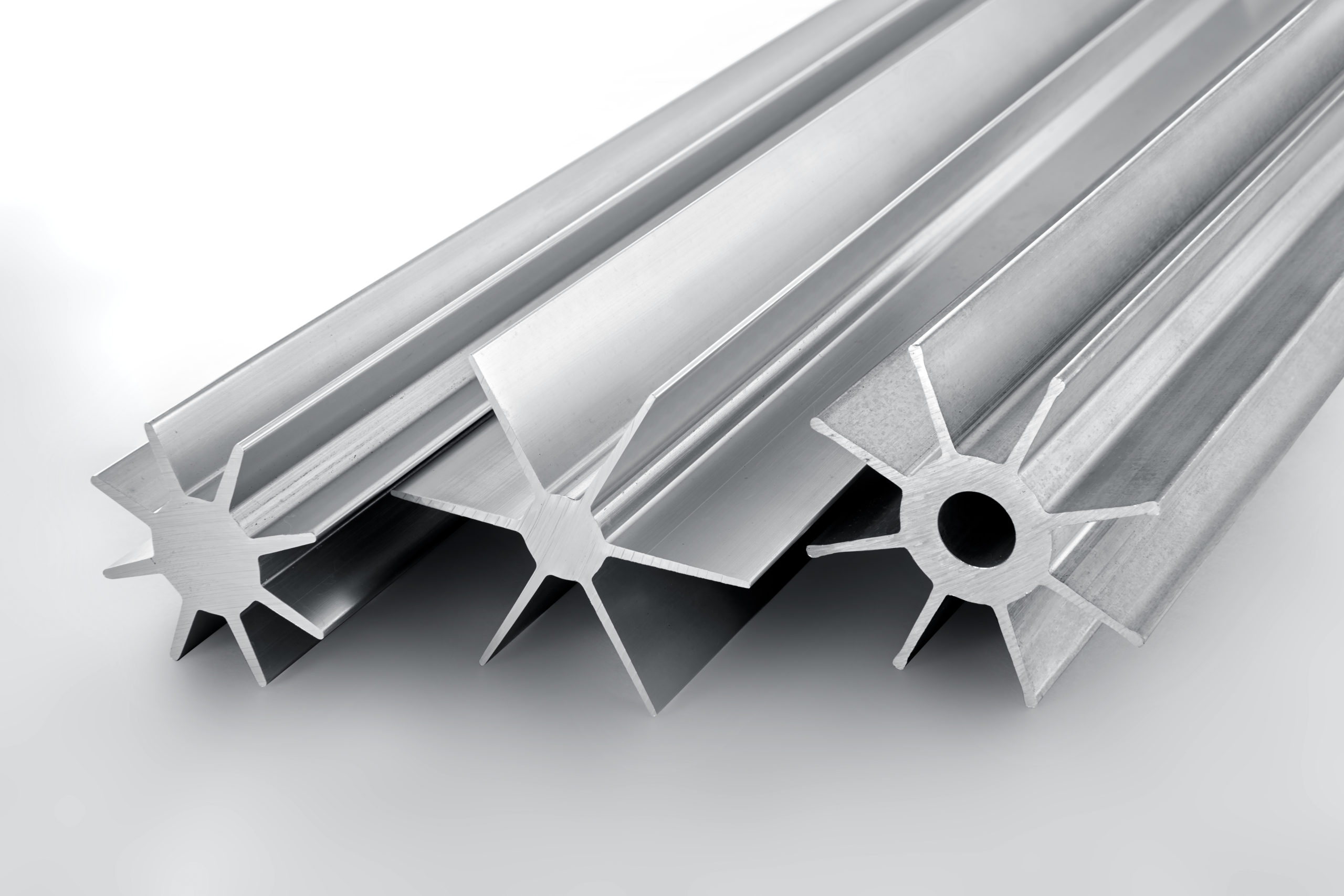

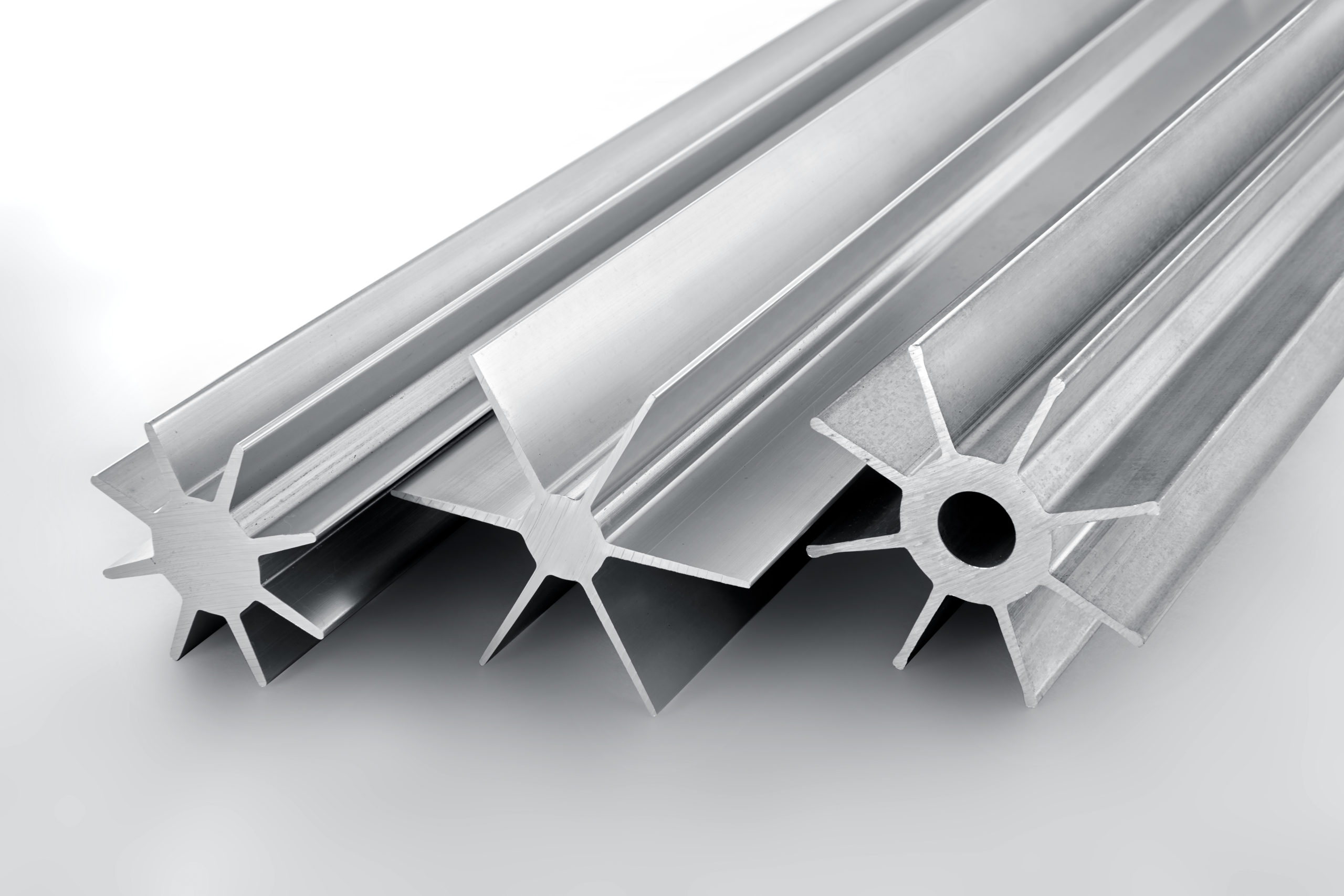

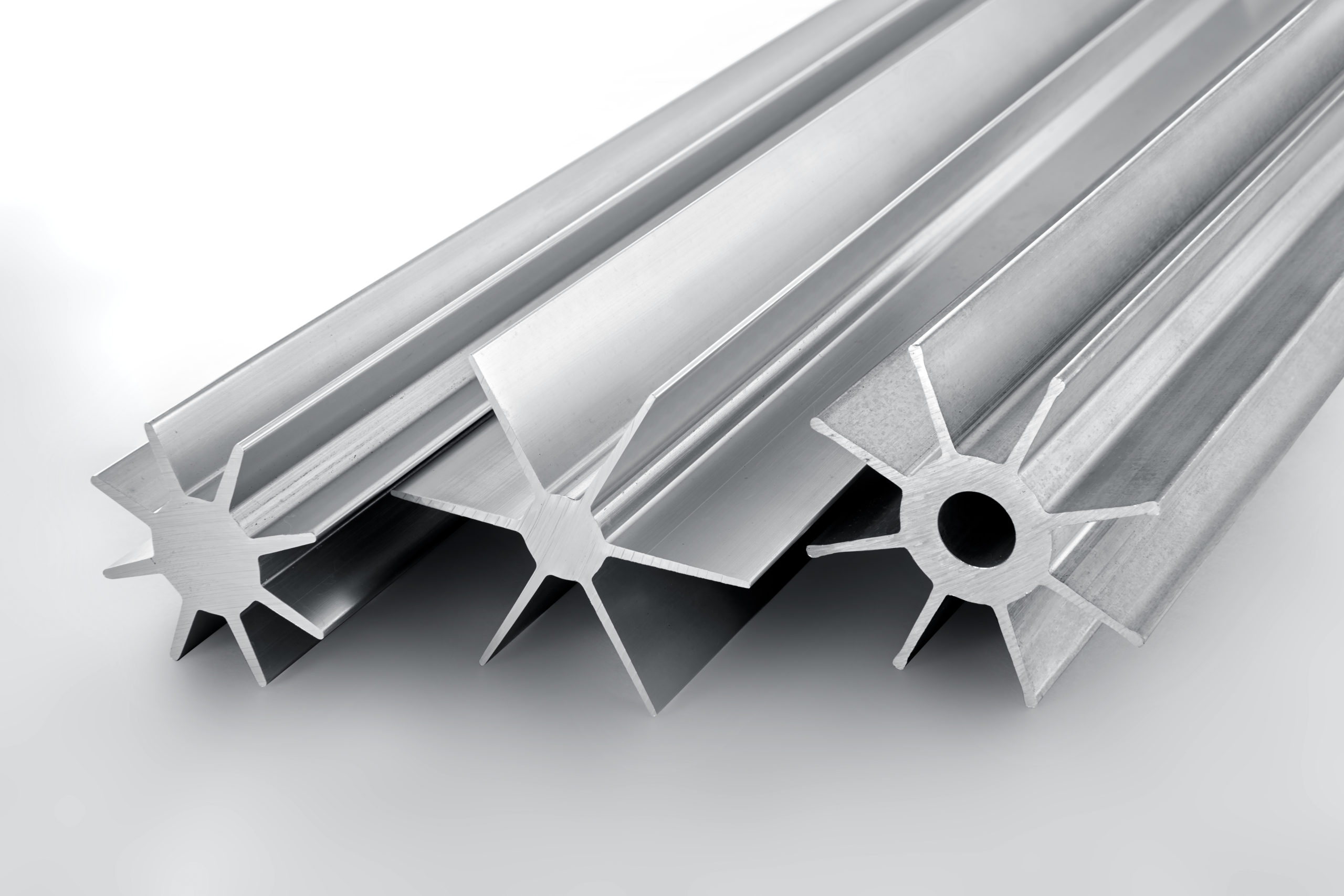

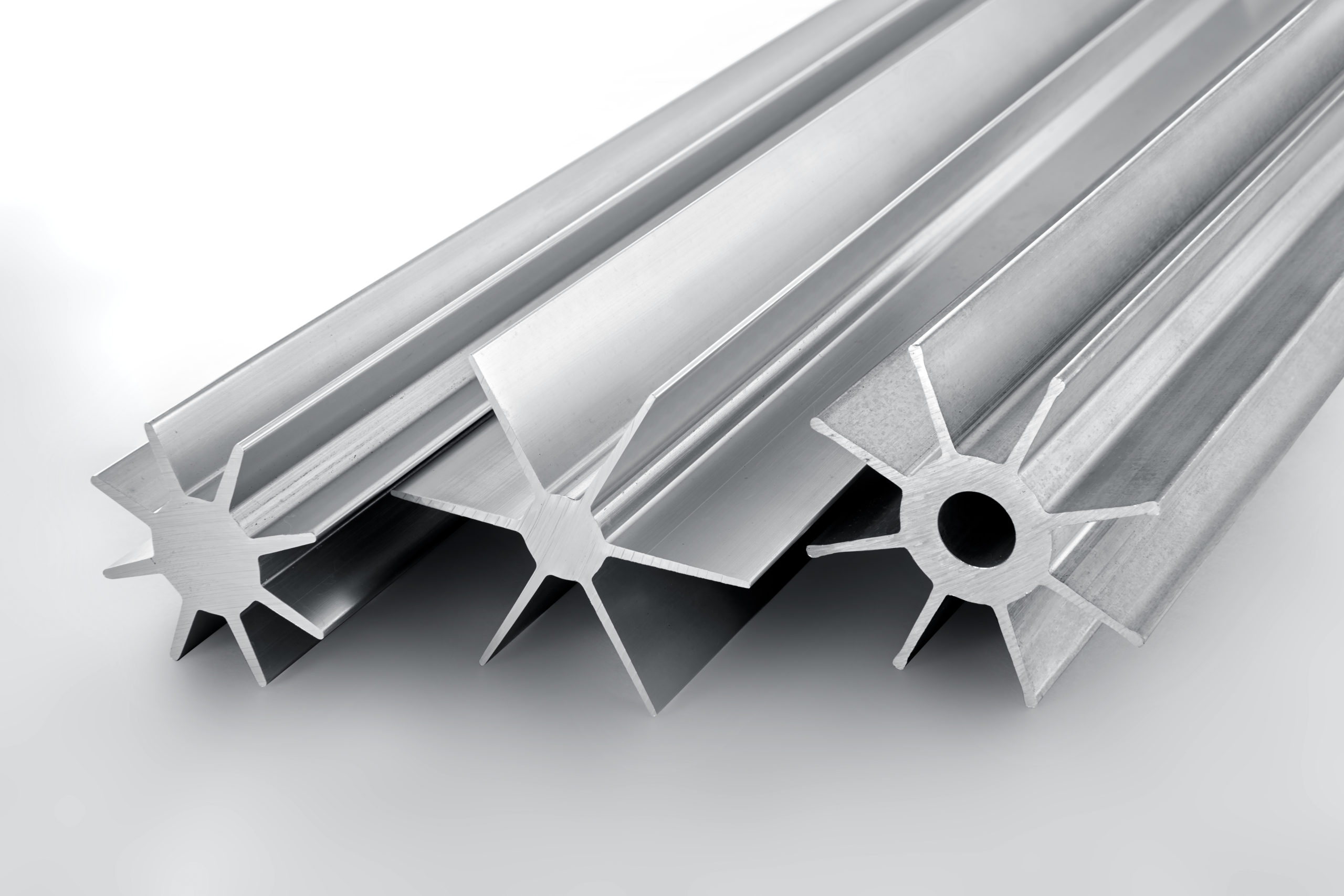

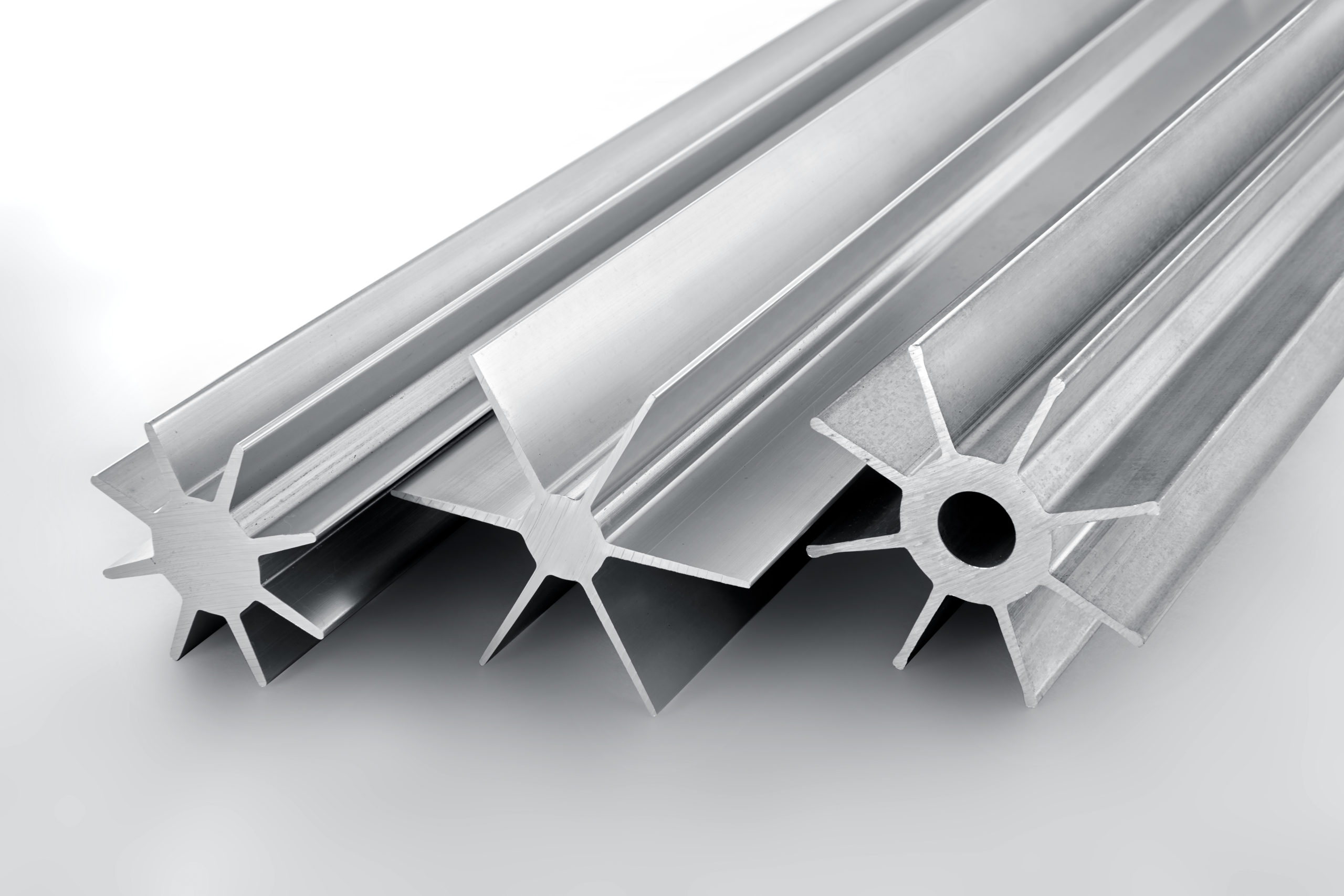

In our manufacturing plant we make use of a wide variety of precision extrusion presses (direct/indirect) & cold drawn machines, vertical and horizontal solution heat treatment & roller hearth furnaces as well as polishing machines and stretchers in house. In combination with our QA laboratory this machinery allows us to maintain the highest quality through our extrusion product portfolio –Aluminum Profile in various applications such as Aircraft Component (7075 – T6511 ; 2024 – T3511). The extruded aluminum profiles could be solid or hollow shape.

In our manufacturing plant we make use of a wide variety of precision extrusion presses (direct/indirect) & cold drawn machines, vertical and horizontal solution heat treatment & roller hearth furnaces as well as polishing machines and stretchers in house. In combination with our QA laboratory this machinery allows us to maintain the highest quality through our extrusion product portfolio –Aluminum Profile in various applications such as Aircraft Component (7075 – T6511 ; 2024 – T3511). The extruded aluminum profiles could be solid or hollow shape.

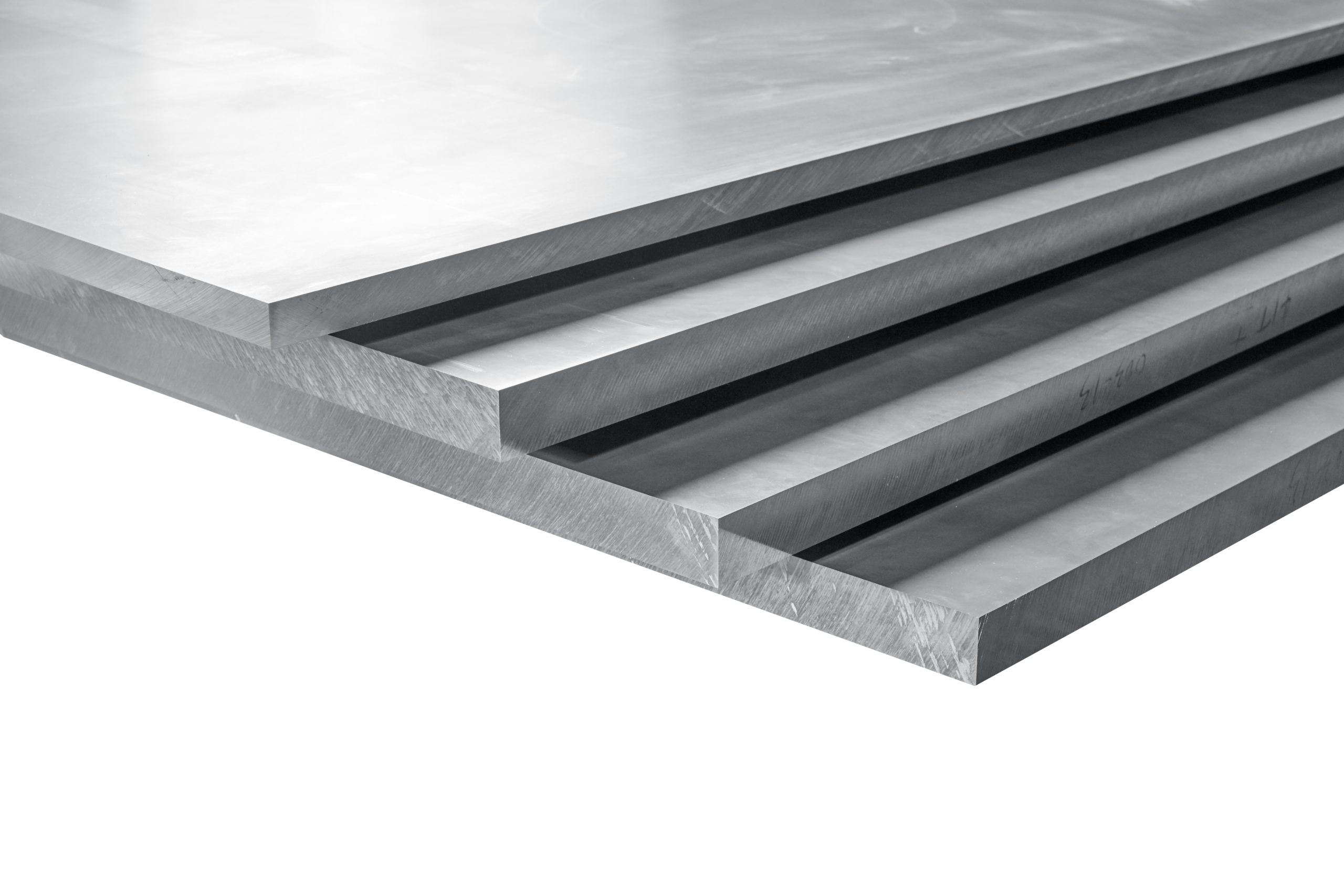

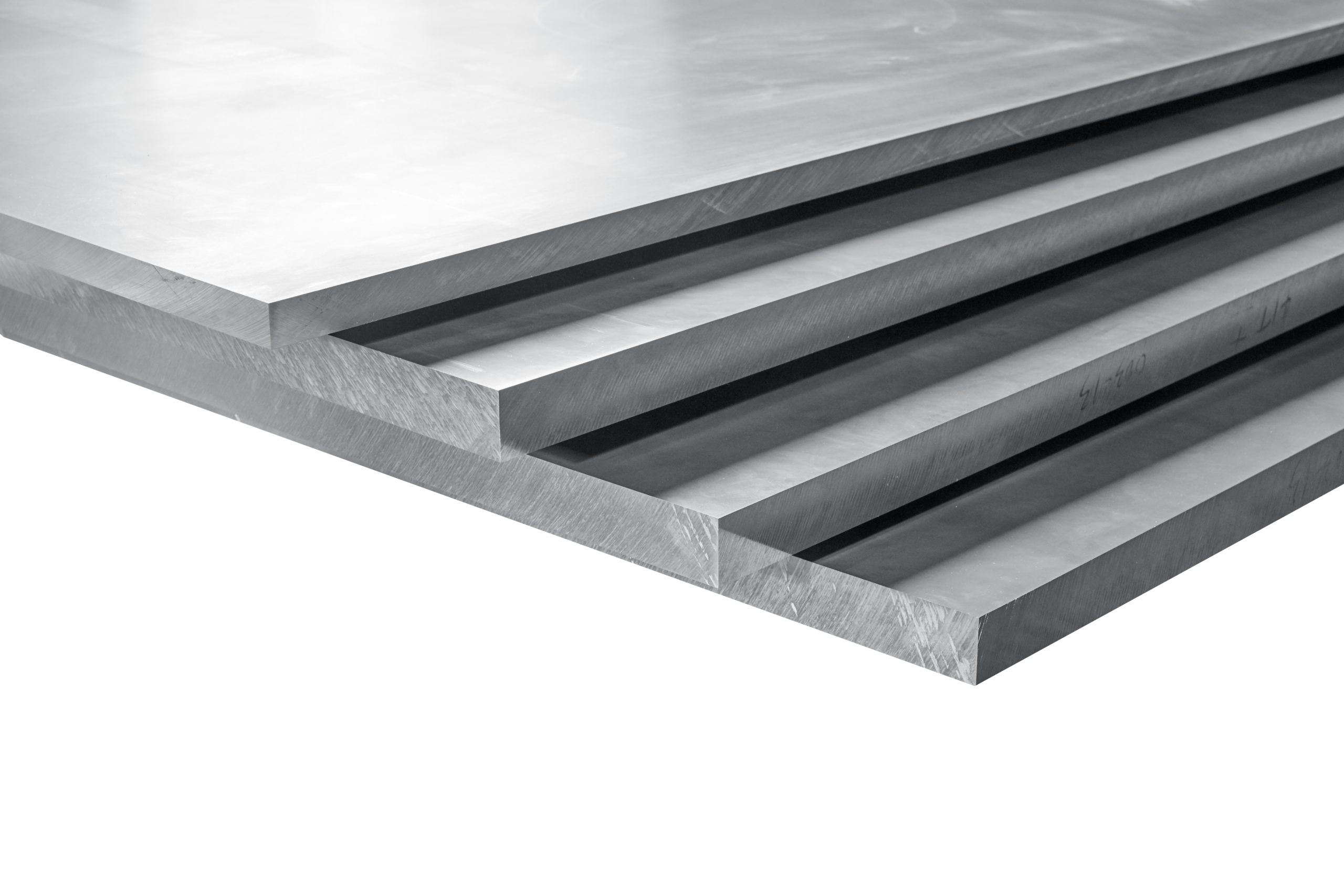

Ye Fong’s aluminum Hot Rolled Plate production focuses on aerospace requirements and we pay great attention to the purity of our hot rolled plates. To meet and satisfy AMS-STD-2154 standards all units undergo strict immersion ultrasonic NonDestructive testing (NADCAP). Our production facilities incorporate the very best hot rolling equipment, continuous roller hearth quenching furnaces, stretching machines. The available alloy & temper includes 2014, 2017, 2024, 2090, 2124, 2219, 2424, 5052, 5083, 5086, 5454, 5456, 6061, 7010, 7049, 7050, 7075, 7150, 7178, 7475…etc.

The company has been approved the certificate ISO9001, ABS, and the certificate AS9100D by AFAQ-AFNOR, and most importantly approved by NADCAP for heat treatment & NonDestructive Testing. Ye Fong is under those quality management system. Ye Fong is seriously keeping the process control and continuous improve action thus not only keep the hardware and software in the optimize condition, but also protect the products quality for the customer carefully.

Ye Fong Aluminum is awarded NADCAP (Heat Treating & NonDestructive Testing),and ABS AS9100 aerospace quality system by AFNOR (French Aerospace qualification), moreover Ye Fong Aluminum certified by Germany TUV system as ISO9001 and ISO14001 quality system.

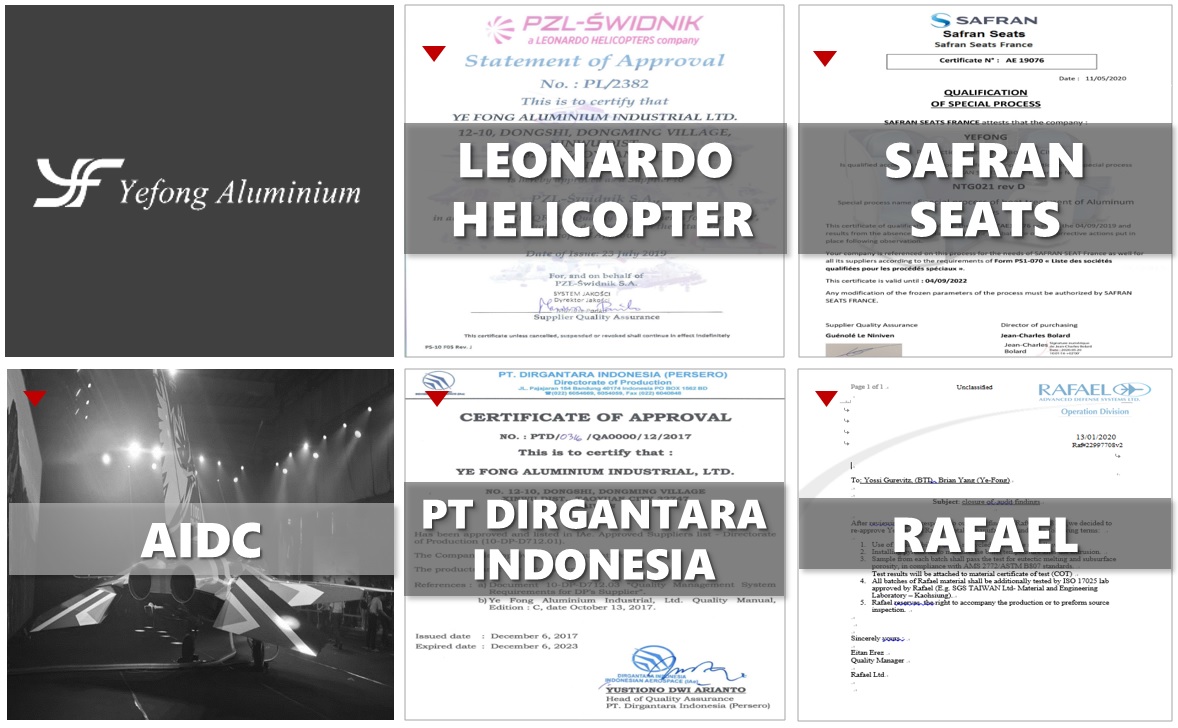

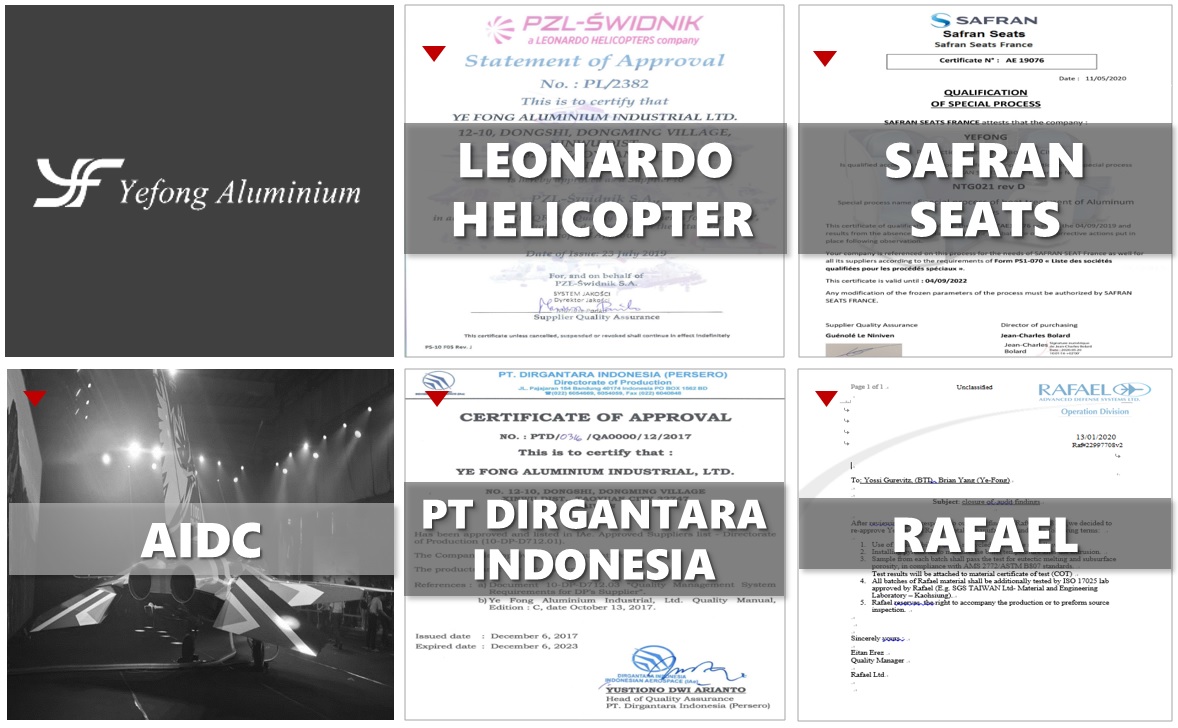

Ye Fong is directly approved by SAFRAN FRANCE, LEONARDO Helicopter, Indonesia Aerospace, AIDC, RAFAEL, EATON, IAI (Israel Aerospace Industries) and WE deliver our aluminum materials to many worldwide customers from Aircraft Manufacturers, Fastener , Automotive, Commercial , High Precision Machining , Medical, Sport and Marine Shipbuilding Industries by third parties.

The company was designed and established by the famous aluminum material specialist Mr. Liu Kuang-Hui, Mr. Liu and his crew have been working in the field of aluminum alloy development for forty years, during that period, the developed many special material applied in automobile component, electronic industry, optical equipment, military & defense, marine shipbuilding, high precision machining, medical industrial and aerospace industry. The customers covered North America、Europe、Africa and Asia, the qualified producers are evaluated as Ye Fong Aluminum is an outstanding aluminum manufacturer/mill in Taiwan.

1) Ye Fong is one of few aluminum material mill in Taiwan which have the full process capability of aerospace-grade aluminum plates, aluminum tubes, aluminum bars, aluminum profile, and aluminum hot-rolled wire rod.

2) Capability of handling extrusion drawing process and heat treatment by ourselves in house

3) Focus on high strength Aluminum alloy R&D and manufacturing (such as 2024 & 7075 & 7050…)

4) Completed certification including ISO9001, ISO14001, AS9100, ABS , NADCAP for heat treating, NADCAP for NonDestructive testing / Comply with international standards such as AMS(WW-T-700/QQ-A-200/QQ-A-225/QQ-A-250)/ASTM/DIN/JIS/BS/EN…etc.

5) Work with world-renowned customers from aerospace, and marine shipbuilding industries.

6) One of a few aluminium wire rod manufacturer in hot rolled process, provide fastener manufacturers with fine grained structures with excellent formability at a competitive price.